With all the chips flying off my Gingery Lathe it seemed like a good idea to protect the bed from chips getting under the carriage. I decided to make my own Lathe Bellows, as those on the market are fairly expensive. What I came up with is fairly cheap, and easy to build.

Step by Step Video of Making The Lathe Bellows:

How To Make Lathe Bellows Video

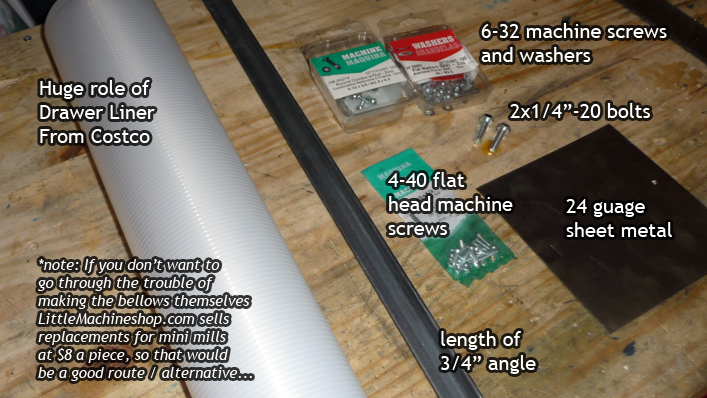

I’ve been fairly alert to materials that would work well for the bellows, and while at Costco noticed a huge role of drawer liner at an extremely reasonable price. The liner was also ribbed which would make setting up the accordion much easier than a straight sheet of plastic. To form the accordion I planned on sewing at the bends, and it worked out quite well though I need to brush up on my sewing skills for sure ![]()

Parts:

* as mentioned in the parts photo above, it became clear to me that an already made bellows could be purchased from littlemachineshop.com which is used for mini-mills. If you don’t want to bother cutting / sewing drawer liner, you can purchase a section from there for $8.

This was a rather on the fly project, and I didn’t plan it out as well as I probably should have, though it came together well enough in the end. The bellows work great, and they don’t bunch up at all when compressed which is a key feature.

The Bellows are mounted to the lathe by a custom angle iron clamp on the headstock end, and a custom sheet metal mount on the carriage side. My Gingery Lathe has very little clearance between the Cross Slide clamp, and the Carriage itself, so I had to determine a method of attachment that would not get in the way of the Cross Slide. The sheet metal worked perfectly, and flat head #4-40 screws were used to screw the sheet into countersunk holes in the Carriage. The sheet metal conformed to the countersunk hole, and thus no screw heads are exposed ( or in the way ).

Definitely checkout the video link above for a step by step on the build.

Cheers,

Morgan

Good job.